DATA CENTRE

AIRFLOW ANALYSIS

Problem Statement

In this age of data, the number of Internet-connected devices is growing aggressively and numerous number of data is generated daily, which must be captured, routed, stored, evaluated and retrieved. The blooming of Internet of Things (IoT) and Industry 4.0 has further enhanced the rely of the different industries on big data and data analytics. Consequently, we can see the growth of demand in date center facilities.

In order to ensure data centers are running 24/7 with very minimum downtime, careful design and management of data centres are utmost important. During data processing process, vast amount of heat is generated which must be eliminated to prevent the server from overheat. Computational Fluid Dynamics (CFD) simulation can be used to optimize building designs and HVAC systems of the data center to ensure that all the servers are cooled effectively (prevent failure) and efficiently (reduce energy consumption).

On Site Visit

During the site visit, the following data will be measured and confirmed before inputting into the simulation:

- Data center layout confirmation

- The temperature and airflow velocity of CRAC and server rack

- Confirmation of hot spots temperature at server rack inlet

Temperature sensors with data acquisition tool, airflow meter and thermal imager will be used

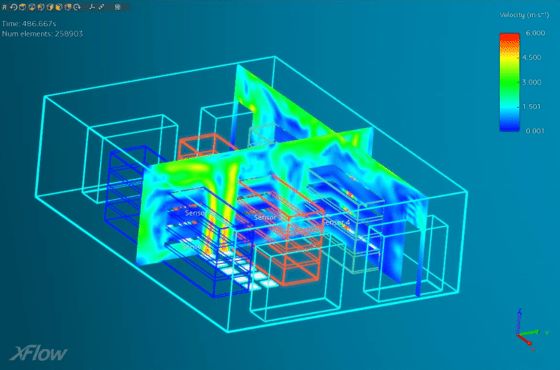

CFD Airflow Analysis

By inputting the data measured from site visit, CFD Airflow Analysis is done using XFlow to simulate and analyse the air flow pattern of the data center based on maximum capacity operating condition.

Improvement

Based on the simulation results, improvement options will be proposed to:

- Remove hot spot area

- Increase the cooling effectiveness and efficiency of the CRAC

Takeaway

At the end of the CFD airflow analysis, data center with optimized airflow pattern is produced which fulfil the temperature requirement and with less energy consumption

Frequently Asked Questions

It all depends on the inputs and boundary condition that is defined in the simulation. Through accurate on-site measurements and data sheet interpretation, we will resemble the simulation to the reality as closely as possible, which will take into account the operating condition of the CRAC.

Through analysing the airflow pattern and temperature distribution, hot spot can be eliminated by adjusting the position of the CRAC / server rack, adding air containment or air guide, increase the number or power of CRAC, etc.

Depending on the scope, the charges depend on the man-day and measurement services included. We are very transparent on the charges. Please contact us to find out more.

Growth is Hard, But We’ve Got You

Don’t hesitate and book your call today to change the future.

Related Product

We start with the end in mind, together with qualitative and quantitative data collection and analysis, we create a business strategy that ensure our clients achieve their goals and experience measurable values.

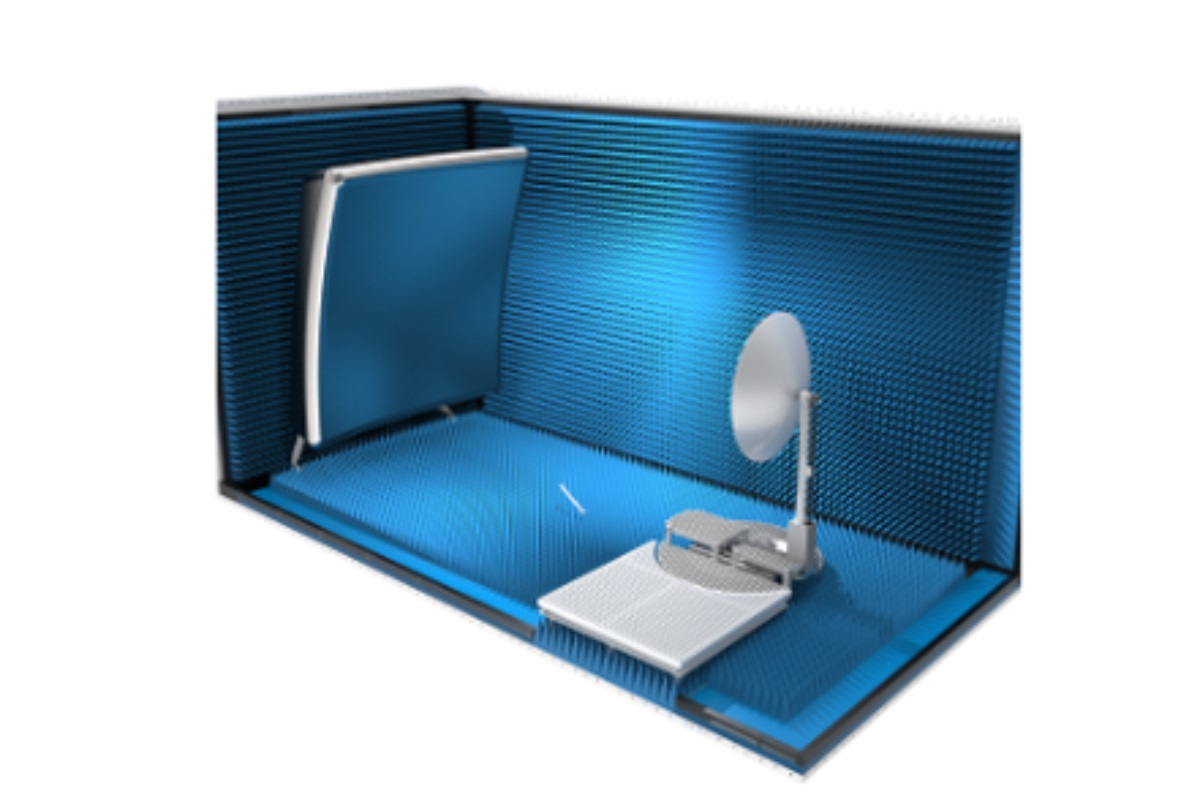

ATENLAB

We have commissioned multiple measurement solutions to research institutes and commercial companies in Vietnam, Thailand, Malaysia, Singapore and Indonesia.

XFlow

The state-of-the-art technology of XFlow enables users to address complex CFD workflows involving high frequency transient simulations with real moving geometries, complex multiphase flows, free surface flows and fluid-structure interactions.