GNR

RESIDUAL STRESS X-RAY DIFFRACTOMETER

Partner of GNR Analytical Instruments Group

GNR, founded in 1984, is an italian producer of X-Ray Diffractometers (XRD) and X-Ray Fluorescence Spectrometers (XRF) for the study of material structure and elemental composition for both scientific and industrial applications.

GNR Head Office and Production Site is located in Agrate Conturbia (Novara), near Lago Maggiore; 20 minutes from MALPENSE Airport.

Stress X- Robotic Residual Stress X-Ray Diffractometer

StressX provides a flexible solution to residual stress determination on samples of any dimensions by the synergy between compact X-Ray diffractometer and 6-axis anthropomorphic robot.

SpiderX - Edge – Portable Residual Stress & Retained Austenite Measurement

SpiderX – Edge is a portable Theta/Theta X-ray diffractometer: it allows performing reliable measurements on production samples and specimens to determine residual stress, retained austenite and to investigate alloys structure and phase composition.

Residual Stress X-Ray Diffractometer

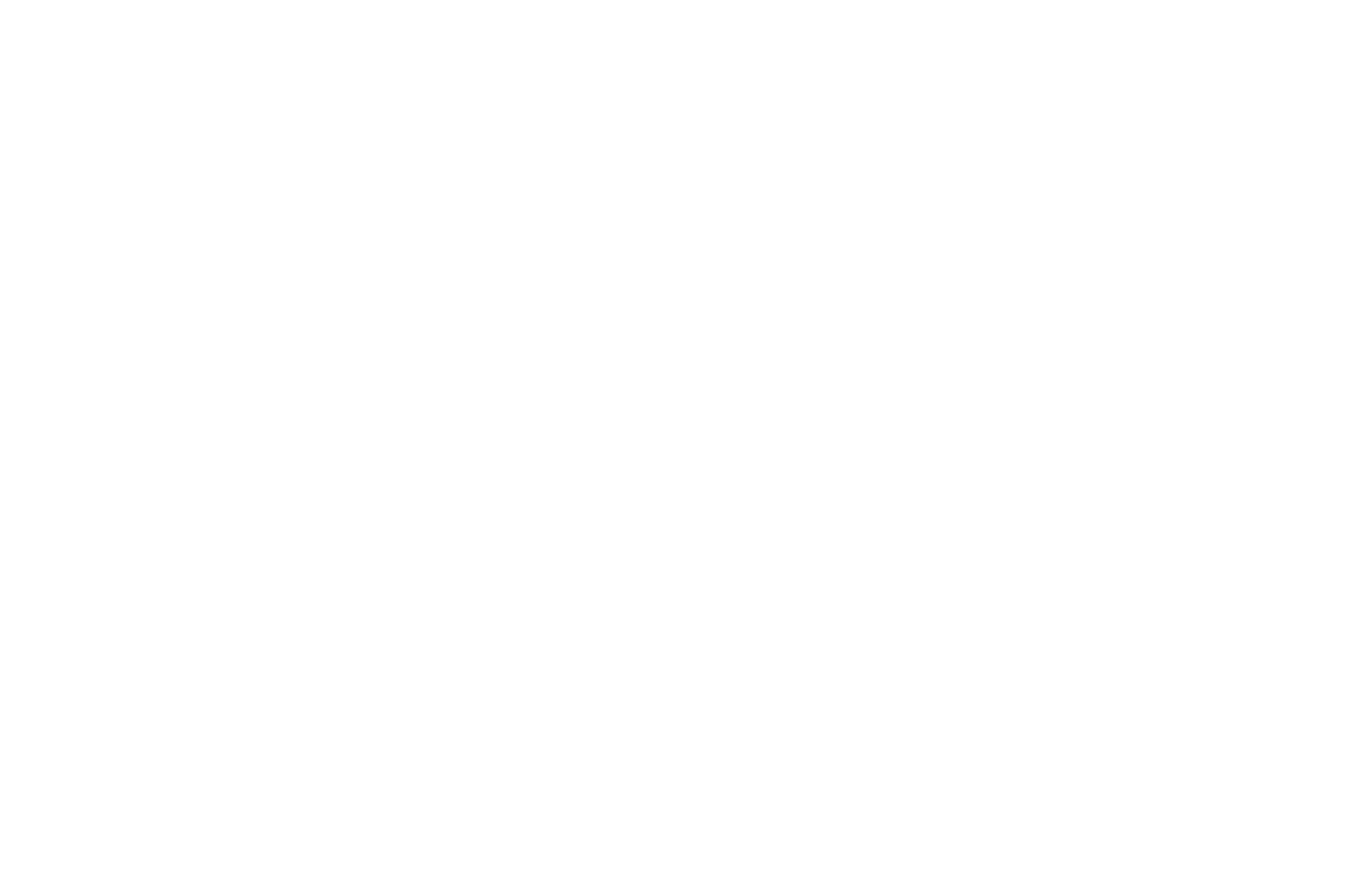

Residual stress could be induced by machining, grinding, rolling, deep drawing, welding, thermal hardening and shot peening; its quantification allows to prevent fatigue damage and to control material’s durability and safety.

X-Ray Diffraction is the conventional and time proven technique for measuring residual stress. Using the interatomic spacing as the ultimate gage length, the X-Ray technique is ideal for and applicable to crystalline materials, especially for metals, but also for ceramics. It measures the absolute stress without the need of an unstressed calibration sample.

Effects of Residual Stress

Residual stress is the stress resident inside a component after all external applied forces have been removed:

Compressive Residual Stress (σ < 0)

- Reduce crack propagation

- Prolongs fatigue life and durability

- Increases strength and corrosion resistance

- Decreases total stress in the areas where high loads are applied

Tensile Residual Stress (σ > 0)

- Increases crack propagation

- Reduces the mechanical performance of materials

Residual Stress quantification allows to prevent fatigue damage and to control material’s durability and safety.

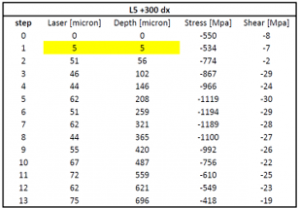

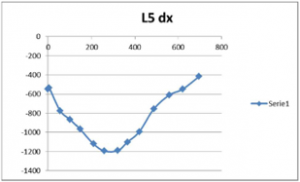

Application: Leaf Spring

This measuring StressX station is equipped with two etching stations and StressX is located to the center in order to operate on both leaf spring sides, allowing sequential etching and measurement steps without removing the sample.

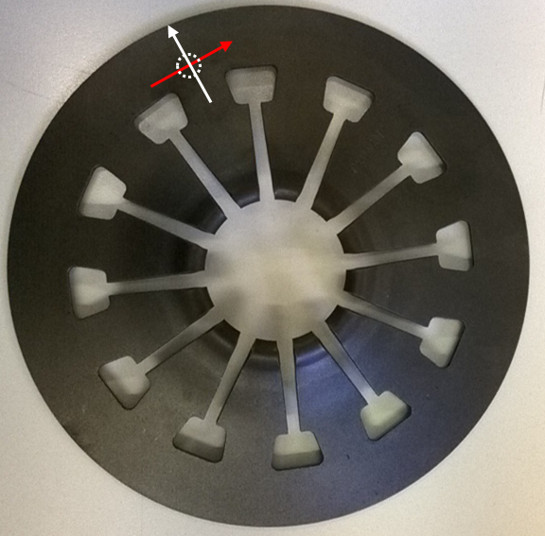

Application: Clutch Manufacturing

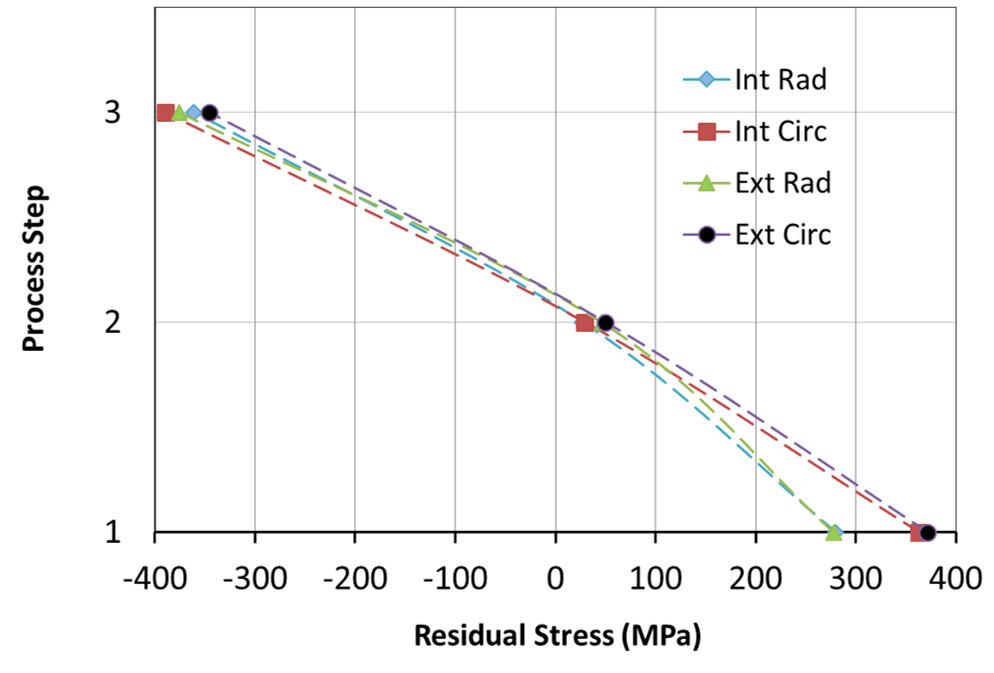

Residual Stress measurement on the diaphragm spring after undergoing casting, induction hardening and shot peening process sequentially.

Application: Welding

Suspensions: Increasing of the tensile residual stress to the center of the weld

Frequently Asked Questions

Growth is Hard, But We’ve Got You

Don’t hesitate and book your call today to change the future.